Environmental Benefits of Using PCB Flex Rigid Boards

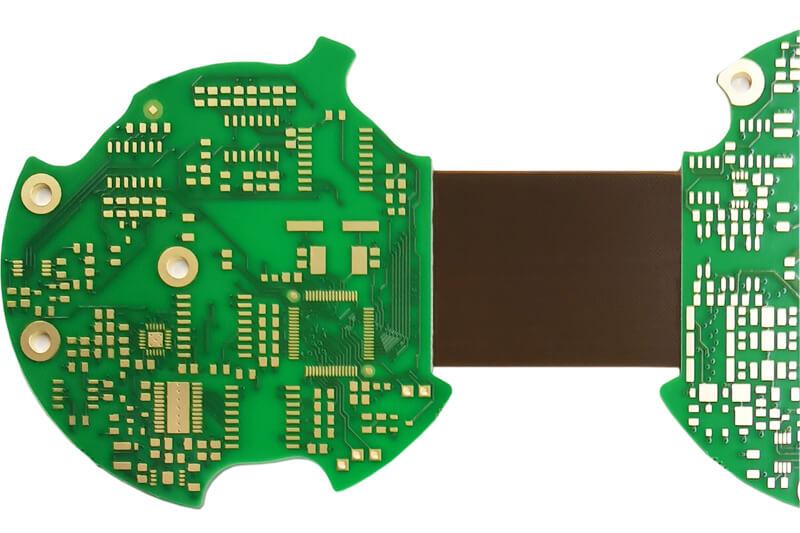

PCB Flex Rigid boards combine the advantages of flexible and rigid PCBs. These boards offer high performance while benefiting the environment.

Reduced Material Usage

Less Raw Material Needed

PCB Flex Rigid boards use fewer raw materials than traditional boards. Their design integrates both flexible and rigid components, reducing the need for separate boards and connectors. This consolidation means less material extraction and processing, which lowers the environmental impact. Using fewer materials also translates into reduced demand for mining and harvesting raw resources, which helps preserve natural habitats and reduces pollution associated with material extraction.

Minimized Waste

The integration of flexible and rigid components in one board minimizes manufacturing waste. Traditional PCB designs often produce excess waste during the cutting and assembly process. PCB Flex Rigid boards streamline this process, reducing offcuts and scrap materials. Additionally, the precision manufacturing techniques used in PCB Flex Rigid production result in more accurate cuts and fits, further decreasing the amount of waste generated. This waste reduction conserves resources and reduces the need for waste disposal and management.

Lower Energy Consumption

Efficient Manufacturing Process

Manufacturing PCB Flex Rigid boards consume less energy. Combining flexible and rigid components into a single board reduces the steps required in production. This efficiency translates into lower energy usage, which helps reduce the manufacturing process’s carbon footprint. The streamlined production process also means fewer machines run simultaneously, decreasing energy consumption. Manufacturers can further enhance energy savings by optimizing production lines, contributing to a more sustainable manufacturing ecosystem.

Enhanced Durability

PCB Flex Rigid boards are more durable, leading to longer product lifespans. Longer-lasting products mean less frequent replacements, reducing energy consumption over time. This durability is a key factor in promoting sustainable electronic design. Durable components reduce the frequency of manufacturing new boards, thereby conserving energy and resources. Furthermore, the robust nature of PCB Flex Rigid boards ensures that devices remain functional for longer periods, decreasing the overall environmental impact of electronic waste.

Improved Design Efficiency

Space-saving Design

PCB Flex Rigid boards offer a compact design, which saves space in electronic devices. Smaller devices require less material and energy to produce. This efficient use of space also reduces the environmental impact of shipping and storage, as more units can be transported in the same amount of space. Compact designs also enable manufacturers to create sleeker and lighter products, further enhancing their appeal and marketability while maintaining eco-friendly standards.

Lightweight Construction

These boards are lighter than traditional rigid boards. Lighter electronics reduce shipping weight, leading to lower fuel consumption and fewer emissions during transportation. This advantage makes PCB Flex Rigid boards a more eco-friendly option. The reduction in shipping weight benefits the environment and lowers transportation costs, making these boards an economically attractive choice for manufacturers. The lightweight nature of these boards also supports the development of portable and wearable technology, expanding their application range.

Enhanced Reliability

Reduced Need for Repairs

The reliability of PCB Flex Rigid boards reduces the need for repairs. Fewer repairs mean fewer resources spent on manufacturing and shipping replacement parts. This reliability supports sustainable practices by minimizing resource use over the product’s life. Reliable components ensure that electronic devices maintain their functionality, reducing the likelihood of malfunctions that require repair or replacement. This conserves resources and enhances user satisfaction by providing dependable products.

Lower Electronic Waste

Reliable PCB Flex Rigid boards contribute to lower electronic waste. Their durability means devices last longer, leading to fewer discarded electronics. Reducing electronic waste is crucial for minimizing the tech industry’s environmental impact. By extending the lifespan of electronic devices, PCB Flex Rigid boards help decrease the volume of e-waste in landfills. This reduction in electronic waste mitigates the release of detrimental chemicals and toxins into the environment, promoting a healthier ecosystem.

Eco-friendly Materials

Use of Green Materials

Manufacturers of PCB Flex Rigid boards often use eco-friendly materials. These materials are less environmentally harmful and can be more easily recycled. Choosing green materials helps reduce the ecological footprint of electronic devices. Eco-friendly materials include biodegradable substances, recyclable metals, and non-toxic adhesives. By incorporating these materials into PCB Flex Rigid boards, manufacturers can significantly decrease the sustainable impact of their products and contribute to a more renewable industry.

RoHS Compliance

Many PCB Flex Rigid boards comply with the Restriction of Hazardous Substances (RoHS) directive. RoHS compliance ensures that the boards do not contain harmful substances. This compliance protects the environment and human health by preventing toxic waste. Adhering to RoHS standards also demonstrates a manufacturer’s commitment to environmental responsibility and regulatory compliance. This compliance can enhance the company’s reputation and attract environmentally conscious consumers who prioritize sustainable products.

Recycling and Disposal

Easier Recycling Process

PCB Flex Rigid boards are easier to recycle than traditional PCBs. Their design allows for simpler separation of materials, making the recycling process more efficient. This ease of recycling helps ensure that valuable materials are recovered and reused rather than ending up in landfills. Efficient recycling processes also reduce the demand for virgin materials, conserving natural resources and lowering environmental degradation. By facilitating recycling, PCB Flex Rigid boards support a circular economy where materials are consistently reprocessed and repurposed.

Reduced Hazardous Waste

Using PCB Flex Rigid boards reduces hazardous waste. Their construction uses fewer toxic materials, making disposal safer for the environment. Proper disposal and recycling of these boards contribute to a cleaner and safer ecosystem. Reducing hazardous waste mitigates the risk of soil and water contamination, protecting wildlife and human health. Manufacturers can play a prominent role in promoting environmental safety and sustainability by choosing PCB Flex Rigid boards.

The Closing NOTE

PCB Flex Rigid boards offer numerous environmental benefits. They reduce material usage, lower energy consumption, and improve design efficiency. Their enhanced reliability and use of eco-friendly materials further contribute to a sustainable future. Manufacturers and consumers can support environmentally responsible practices and reduce their ecological footprint by choosing PCB Flex Rigid boards. These boards represent a step forward in creating more sustainable electronics, benefiting both the industry and the planet!