How to Choose Reliable Marine Spare Parts and Suppliers?

Maintaining the safety, efficiency, and lifetime of marine vessels depends on the careful choice of dependable marine replacement parts and reliable providers. Though it might be difficult and time-consuming, this step is necessary for seamless marine operations. This post offers thorough advice on negotiating the world of maritime spare parts and providers, therefore enabling vessel owners and operators to make wise decisions.

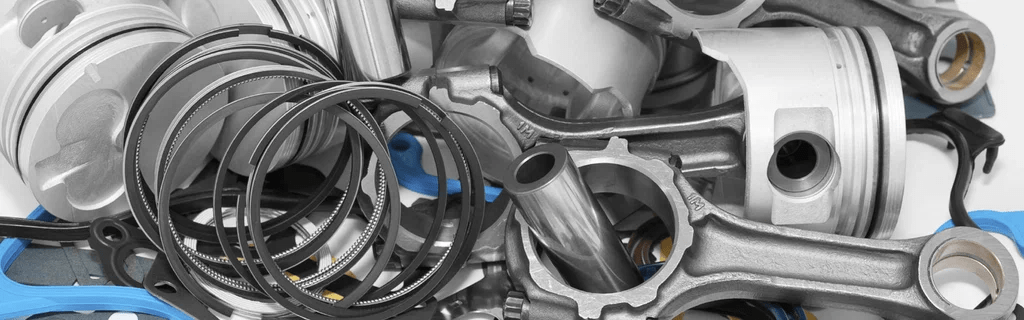

Recognizing the Value of Superior Marine Spare Parts

The overall safety and performance of ships depend critically on high-quality marine parts and supplies. Using inferior or counterfeit components can cause equipment breakdowns, increased downtime, and potentially dangerous situations. Conversely, premium replacement parts can increase fuel efficiency, prolong the lifespan of maritime equipment, and ultimately lower maintenance expenses.

One should understand that not every spare component is produced equally. Some may be produced using poorer materials or to less standards, therefore compromising their dependability and lifetime. Maintaining the integrity of marine vessels and guaranteeing compliance with maritime laws depend on real, premium spare parts from reliable vendors being invested in.

Finding trustworthy marine spare parts suppliers

Maintaining the validity and quality of the components used in vessel maintenance and repairs depends critically on reliable marine spare parts providers. Reliable providers usually have a solid track record in the maritime sector, a thorough awareness of marine equipment, and a dedication to client satisfaction.

Examining certificates and accreditations helps one to choose reliable vendors. Seek vendors accredited by reputable classification societies or industry organizations. Many times, these certificates show that the supplier follows best practices in the maritime sector and maintains high levels of quality.

The inventory and stock availability of the provider should also be taken into account somewhat highly. Usually keeping a thorough inventory of marine spare parts covering a wide spectrum of vessel types and equipment manufacturers, reliable marine spares suppliers. This guarantees their ability to supply the required components quickly, therefore lowering vessel downtime and operating disturbance.

Important factors to consider while selecting a marine replacement parts provider include customer service and after-sales assistance. Search for vendors who give thorough product information, technical assistance, and experienced staff able to help with part selection and compatibility problems.

Evaluating Marine Spare Part Quality

Evaluating marine spare parts calls for a thorough analysis of several elements. First and most importantly, it is vital to confirm the part’s legitimacy. Since they are built and produced to satisfy particular performance and safety criteria, genuine components from original equipment manufacturers (OEMs) are usually the safest option.

Still, there are also excellent aftermarket components on hand that may provide reasonable performance for less money. When thinking about aftermarket components, one should investigate the manufacturer’s quality control procedures and reputation. Search for components that satisfy international standards like ISO 9001 or that are certified by classification bodies.

Another important consideration is the component makeup of spare components. Because marine settings are hostile and corrosive, components have to be built from materials that can survive these circumstances. For usage in saltwater conditions, for instance, parts constructed of marine-grade stainless steel or corrosion-resistant alloys are frequently more suited.

One should also take into account the methods of manufacturing applied to generate the replacement parts. Higher accuracy and greater performance can come from advanced production processes such as 3D printing or precision machining. Inquire of manufacturers about their quality control systems and production techniques to make sure the items satisfy necessary criteria.

Analyzing Value and Cost

Though cost is a major element in choosing marine spare parts, it shouldn’t be the only one. Not necessarily the most cost-effective over the long run is the least expensive choice. Rather, concentrate on identifying the best value for money by weighing elements including expected lifespan, durability, and part quality.

When pricing comparisons, consider any extra expenses including customs taxes, shipping, or necessary alterations. Although some vendors have reduced upfront costs, their shipping costs or longer lead times may affect the purchase’s overall value.

Additionally worth thinking about are the possible savings made by establishing long-term supplier relationships or mass buying. Discounts for big orders or repeat business are provided by many vendors, which can help lower general procurement costs.

Ensuring Authenticity and Compatibility

Maintaining vessel performance and safety depends on spare parts fitting for current equipment. Before you buy, always check the part numbers and specifications. If feasible, review the original equipment manufacturer’s documentation or seek guidance from certified maritime experts to confirm compatibility.

Work with reliable vendors who can give paperwork proving the validity and source of their goods to protect against fake components. Certificates of conformity, material test reports, or traceability records might all fall here. Be aware of offers that appear too good to be true, since they may suggest counterfeit or poor parts.

Some vendors utilize modern technology such as QR codes or RFID tags to assist verify the legitimacy of their parts. These technologies can give extra assurance and make it easier to trace components throughout their lives.

Building Strong Supplier Relationships

Developing good ties with marine spare parts suppliers may lead to various benefits, including lower prices, improved service, and access to technical assistance. Spend some time clearly expressing your needs and objectives; furthermore, be receptive to supplier comments on how best to streamline your spare parts buying process.

Frequent performance reviews assist in keeping high standards and point up areas needing work on the supplier relationship. When evaluating supplier performance, take into account elements such as delivery dependability, product quality, answerability to questions, and technical assistance.

Using Technology to Manage Spare Parts

Technological developments are changing marine spare part procurement and management. Many vendors today provide online catalogs and purchasing systems that simplify the search and purchase of the correct components. To ensure the right components are chosen, these systems can incorporate thorough product information, 3D models, and compatibility data.

Additionally helping to maximize spare part inventory control are predictive maintenance solutions, which employ sensors and data analytics to foresee equipment faults. Anticipating when parts are likely to break helps vessel operators purchase new parts ahead, therefore lowering downtime and increasing general efficiency.

Conclusion

A key component of vessel management that calls both constant attention and careful thought is selecting dependable marine spare parts and vendors. Focusing on quality, authenticity, and value will help vessel operators make sure they have the correct components on hand as needed, thereby reducing downtime and optimizing operational effectiveness. Key tactics for success in this field are developing close ties with reliable vendors, using technology, and applying sensible inventory control techniques. By using the correct strategy, vessel operators may confidently negotiate the complicated realm of marine spare parts procurement, therefore guaranteeing the safety, dependability, and performance of their boats for many years to come.