The Importance of Regular Power Supply Testing in Ensuring Efficiency and Safety

Introduction to Power Supply Testing

Welcome to a world powered by electricity, where the reliability of our power supply systems is crucial for both efficiency and safety. Imagine a day without electricity – no lights, no devices, no modern conveniences. It’s clear that power supply testing plays a vital role in ensuring that we can continue to enjoy the benefits of our electrically driven lives. Let’s delve into the importance of regular power supply testing and why it should not be overlooked.

Understanding the Importance of Regular Testing

Regular power supply testing is crucial for ensuring the efficiency and safety of electrical systems. By conducting routine tests, you can identify any potential issues before they escalate into major problems. This proactive approach helps prevent costly downtime and repairs.

Understanding the importance of regular testing means acknowledging that power supply failures can lead to disruptions in operations, financial losses, and even safety hazards. By staying ahead of these risks through consistent testing, businesses can maintain continuity and protect their investments.

Moreover, regular testing allows you to comply with industry regulations and standards. It demonstrates your commitment to upholding safety protocols and quality control measures. Ignoring or neglecting these requirements could result in fines or legal consequences for non-compliance.

In essence, prioritizing regular power supply testing is not just about maintaining functionality; it’s about safeguarding your business, employees, customers, and assets from potential harm or setbacks due to unforeseen electrical issues.

The Dangers of Neglecting Power Supply Testing

Neglecting power supply testing can pose serious risks to both efficiency and safety in any setting. A failure in the power supply system can lead to unexpected downtime, disrupting operations and causing financial losses. Moreover, unchecked issues with power supply can result in damage to equipment, potentially leading to costly repairs or replacements.

Inadequate testing may also increase the likelihood of electrical faults and even fires, putting employees and property at risk. Without regular inspections and assessments, underlying problems within the power supply infrastructure may go unnoticed until they escalate into larger issues.

By neglecting power supply testing, businesses are essentially playing a dangerous game of chance with their operations. It’s crucial to prioritize routine testing to identify potential concerns early on before they evolve into significant hazards that could impact productivity and jeopardize safety standards.

How to Conduct a Proper Power Supply Test

To conduct a proper power supply test, start by unplugging all devices connected to the power source. This ensures accurate results and prevents any damage during testing. Next, inspect the power cables for any signs of wear or damage that could affect the test.

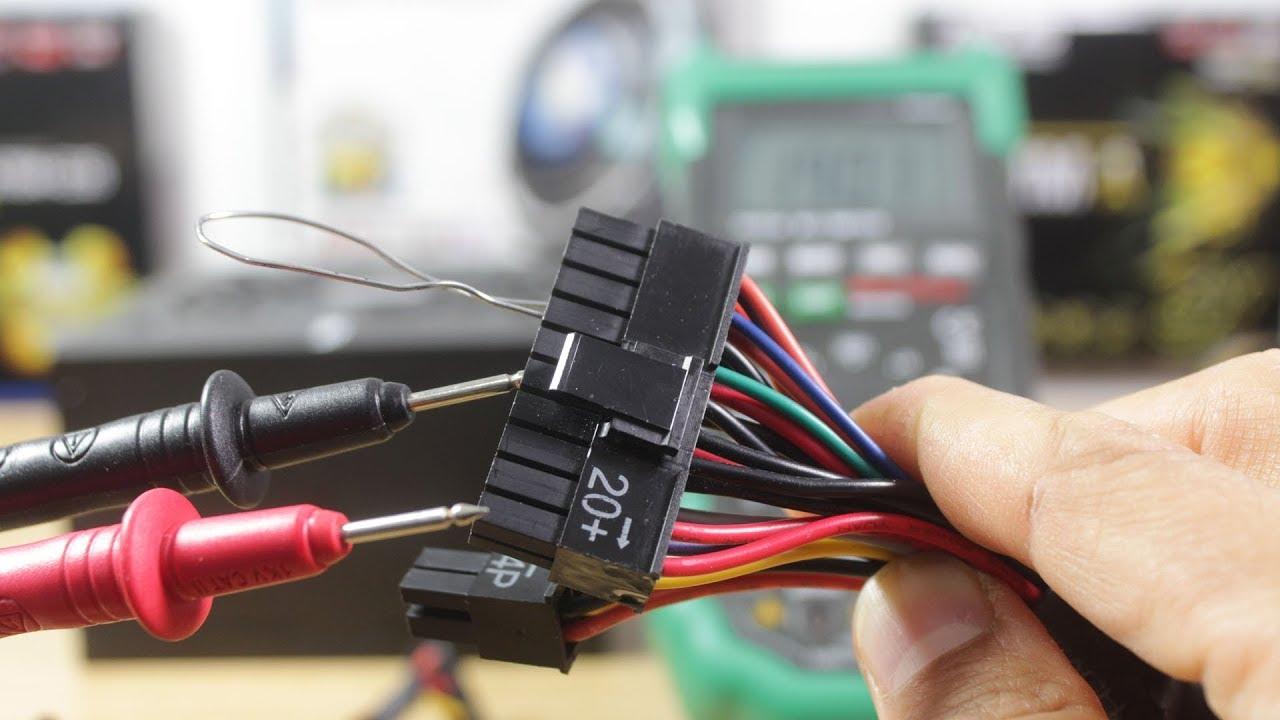

Use a multimeter to measure voltage output from the power supply unit. Make sure to set the multimeter to the appropriate range before taking measurements. Check for consistent voltage levels across different components of the power supply.

Test for continuity using a continuity tester to ensure there are no breaks in electrical connections within the power supply unit. This helps identify any potential issues with wiring that could lead to malfunctions or safety hazards.

Document your findings and compare them against manufacturer specifications for reference. Regularly conducting these tests can help prevent unexpected failures and ensure optimal performance of your power supply system.

Tools and Equipment Needed for Testing

When it comes to conducting power supply testing, having the right tools and equipment is essential. One of the key items you’ll need is a multimeter, which helps in measuring voltage, current, and resistance levels within the power supply system. A digital oscilloscope is also crucial for analyzing waveforms and ensuring they are stable.

You’ll also require a load tester to simulate different loads on the power supply unit to check its performance under varying conditions. A power supply tester can help quickly determine if there are any issues with the output voltages. Additionally, a surge protector can safeguard your equipment during testing from any unexpected power surges.

Don’t forget about safety gear like insulated gloves and goggles to protect yourself while working with electricity. Proper labeling materials will help you keep track of tested components easily. Having these tools at hand ensures thorough and accurate power supply testing every time.

Benefits of Regular Power Supply Testing

Regular power supply testing offers a range of benefits that go beyond just ensuring the efficiency and safety of your electrical systems. By conducting routine tests on your power supply, you can identify any potential issues or weaknesses before they escalate into more significant problems. This proactive approach can help prevent unexpected downtime and costly repairs in the future.

Moreover, consistent testing allows you to maintain optimal performance levels for your equipment and machinery. By monitoring the health of your power supply regularly, you can prolong the lifespan of your devices and reduce the risk of sudden failures. This not only saves you money on replacements but also keeps your operations running smoothly without interruptions.

Additionally, regular power supply testing is essential for compliance with industry regulations and standards. Many organizations require proof of periodic testing to adhere to safety guidelines and legal requirements. By staying up-to-date with these assessments, you demonstrate a commitment to maintaining a secure working environment for both employees and customers alike.

Conclusion and Recommendations

Regular power supply testing is crucial for maintaining efficiency and safety in any electrical system. By conducting routine tests, you can detect potential issues early on, prevent costly downtime, and ensure the safety of both personnel and equipment.

To effectively conduct power supply testing, make sure to use the right tools and equipment such as multimeters, oscilloscopes, and load testers. Follow proper procedures and guidelines to accurately assess the condition of your power supply.

Prioritizing regular power supply testing is a proactive approach that can save you time, money, and potentially avert dangerous situations. Stay ahead of potential problems by incorporating routine testing into your maintenance schedule to keep your systems running smoothly and safely.